日本語

日本語 English

English

We aim to fulfill our corporate social responsibility and grow together with local communities.

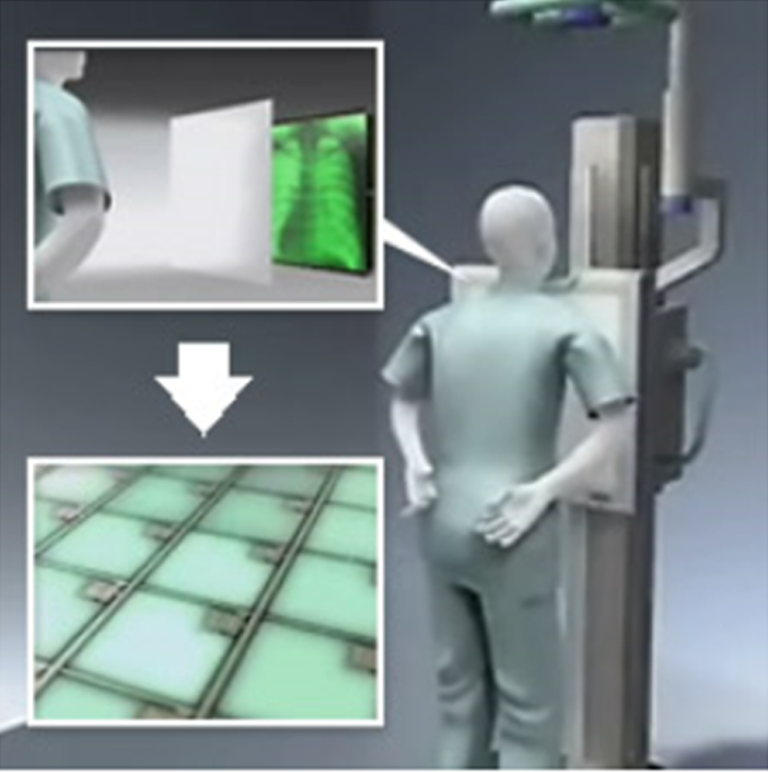

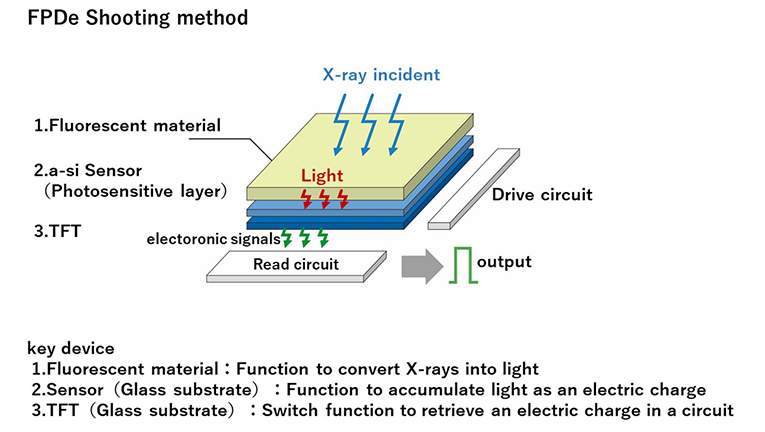

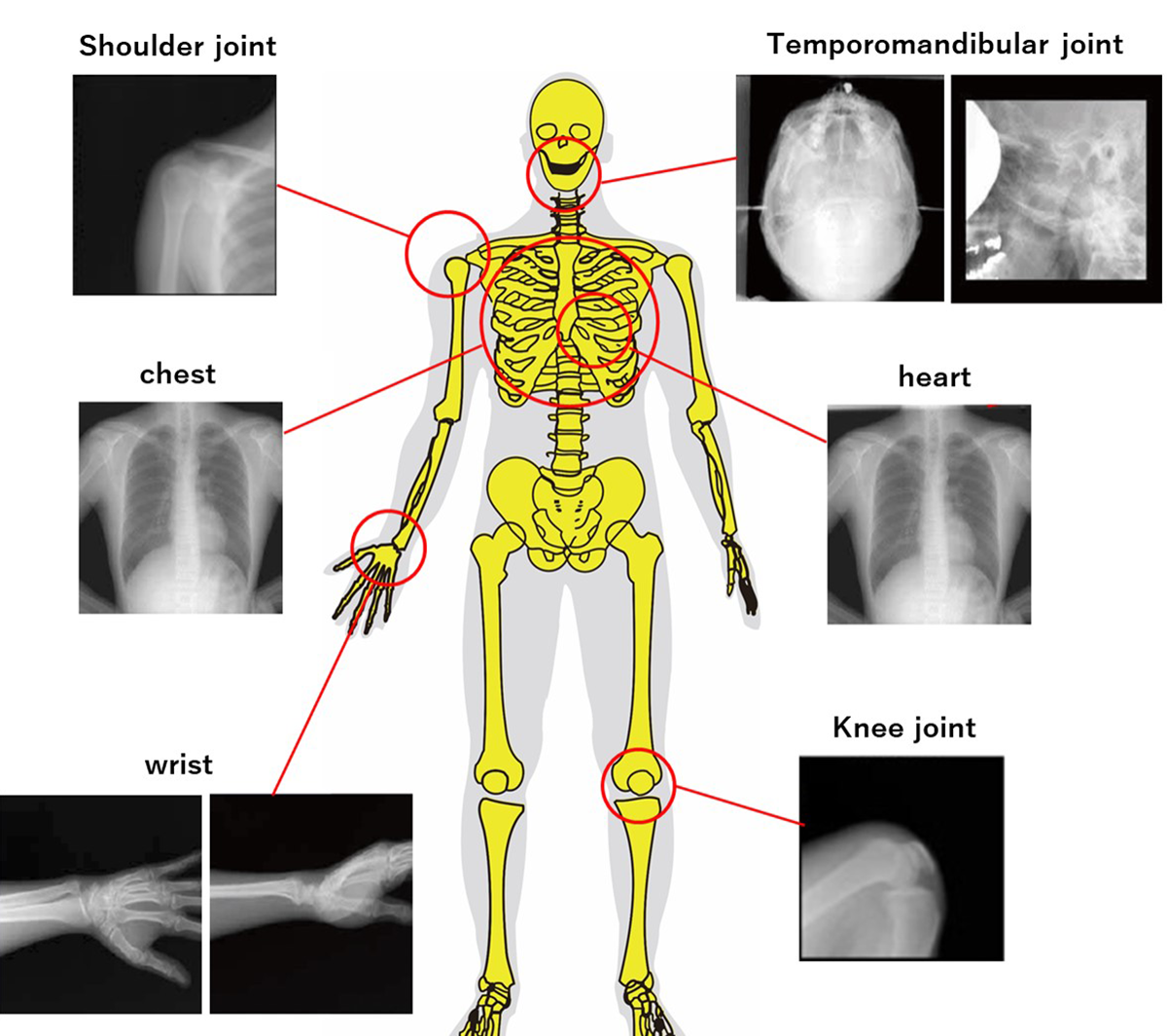

Canon's medical equipment business has a long history of more than 70 years. Based on our proprietary technology, and using advanced digital technologies such as image processing technology and sensor technology, we develop, produce, and sell medical imaging equipment, ophthalmic devices, and various measuring instruments. Under the development concept of "more patient-friendly medical care," we will respond to diversifying medical needs with our advanced technologies, such as efficiently managing examinee information and test results using our comprehensive digital capabilities.Canon Components has been involved in the production of diagnostic medical devices such as flat panel detectors (digital radiography), fundus cameras, and ophthalmotonometers. In October 2019, we started production of industry camera devices.

Hybrid full-automatic OCT and fundus camera OCT-R1※

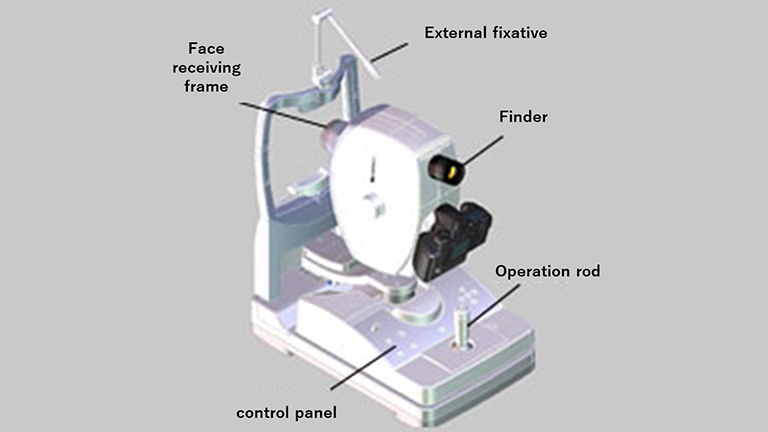

Mydriatic/Non-mydriatic Integrated fundus camera CX-1

full auto tonometer TX-20P

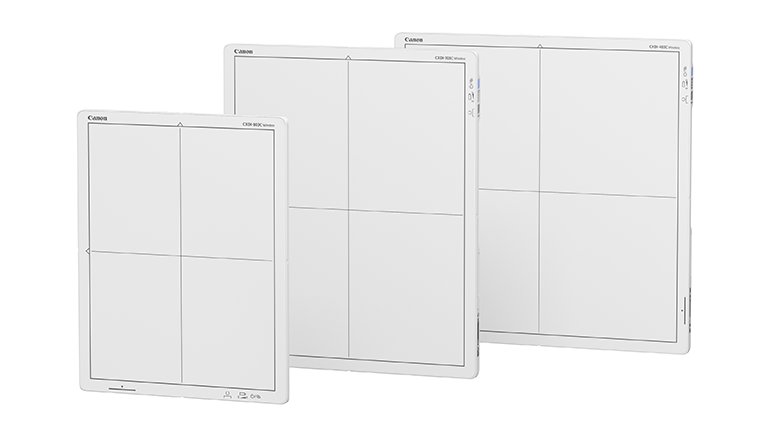

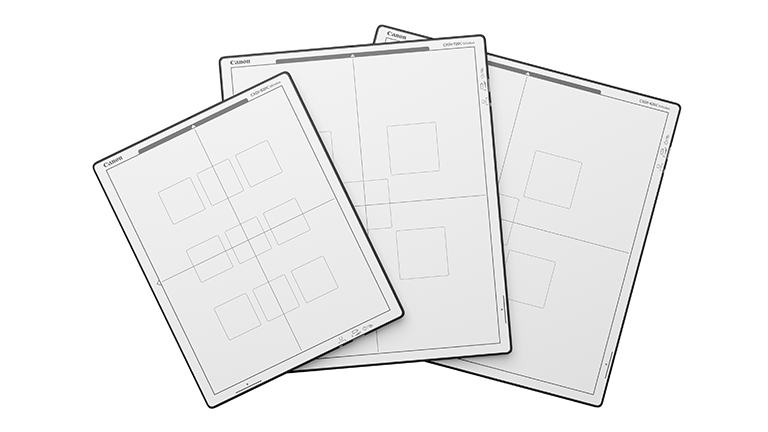

CXDI-Pro

low-dose standard model

CXDI-Elite

Low-dose, lightweight, waterproof, and dust-proof models

Head-separated 3-CMOS camera

(4K camera) IK-4KH_4KE

Head-separated 3-CMOS camera

(Full HD Camera) IK-HD5U

Integrated 1-CMOS camera

(Full HD Camera) JCS-HR5U

※OCT=「Optical Coherence Tomography」

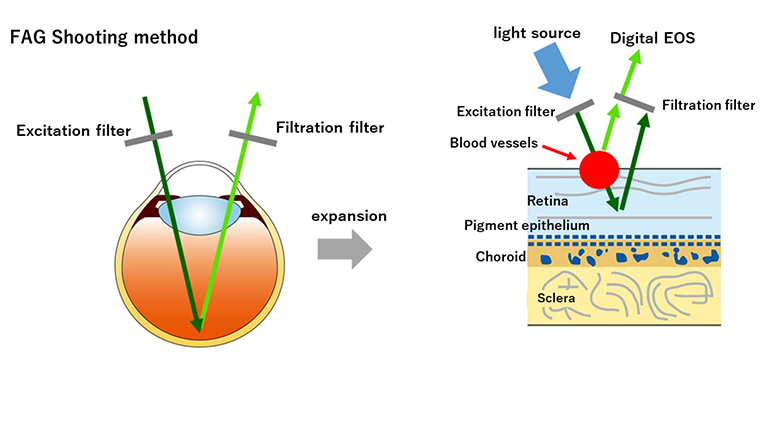

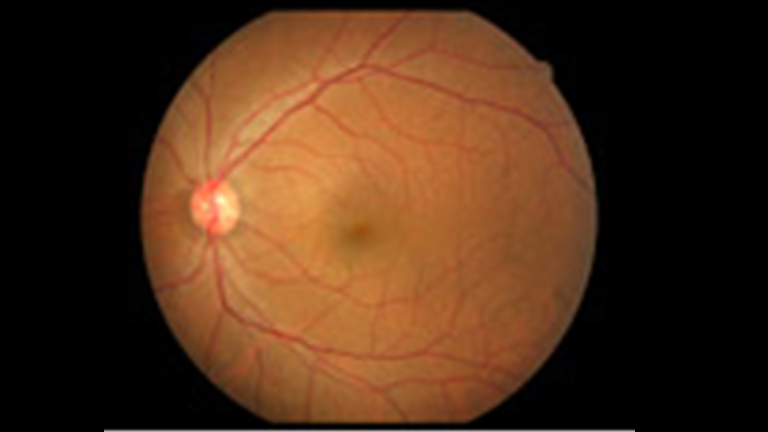

It is a device that takes pictures of the retina of the human eye.Pictures are taken through the small pupil while shining light into the eye.The human eye (mainly consisting of cornea, lens, and pupil) is an optical system. Lighting and photographing are done through one objective lens.

The use of a high-quality video engine achieves faithful color reproduction and unparalleled image quality. These features have been implemented by improving the adjustment accuracy to the limit of performance with the skill of a craftsman’s skill called “diagonal pixel shifting.” A wide range of products for medical applications are available.

Adopted in many medical fields such as hospitals, universities and research institutes.

Installed in electron microscopes and surgical microscopes.

The production system consists of four divisions: the Assembly Division (flat panel detectors, ophthalmic cameras, and medical camera equipment), the Production Management Division (planning and control), the Engineering Division (production and product technology), and the QA Division (quality assurance and response to external organizations). These divisions are closely coordinated to support production. Through this production system, products are finished to be ready for customer use and shipped. Canon Components will continue to provide high-value-added products and contribute to the development of the medical industry.

[Assembly department]

Clean room of flat panel detectors

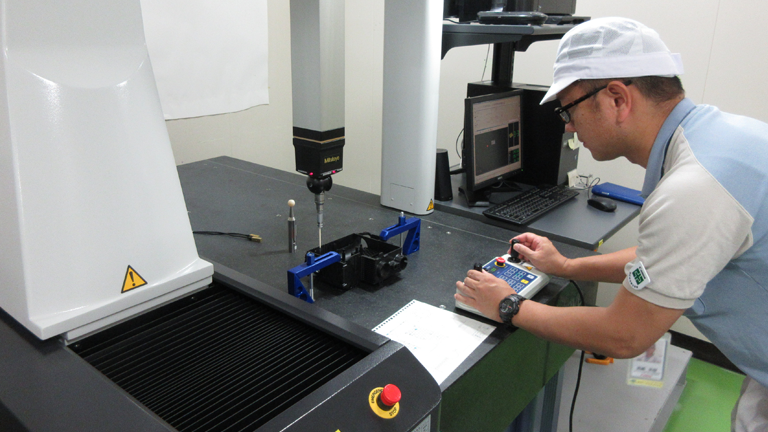

[Quality Assurance department]

Measurement work for Quality Assurance

[Quality Assurance department]

work for Quality Assurance

[Technology department]

Mechanical CAD design for new product

[Assembly department]

Clean room of medical camera equipment

[Quality Assurance department]

final inspection of medical camera equipment