日本語

日本語 English

English

We aim to fulfill our corporate social responsibility and grow together with local communities.

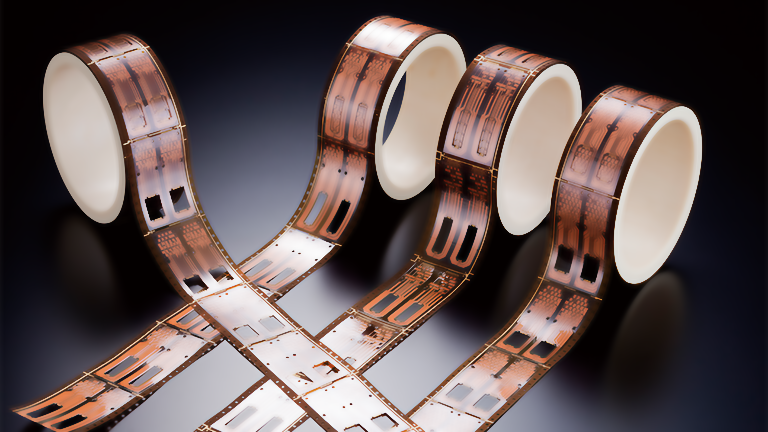

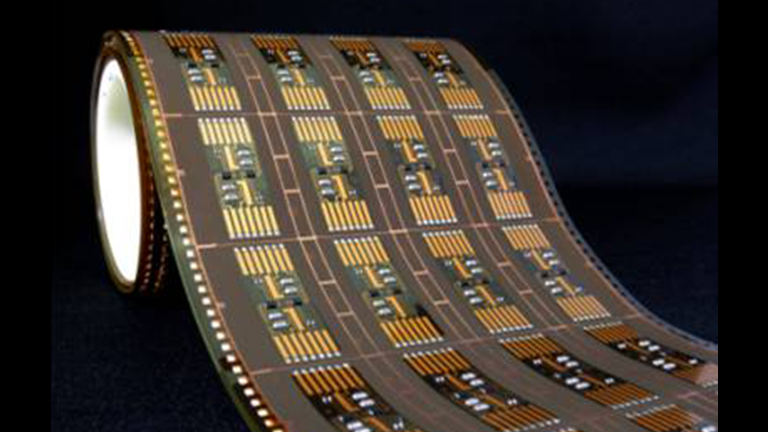

Reel-to reel method can produce TAB and COF of the high productivity by automation including feed and winding and of high quality by the non contact method that completely minimizes human intervention. And,we can meet to a wide range of customer’s requests by producing with sheet size delivery.

TAB is an abbreviation for Tape Automated Bonding, which is the name of an IC mounting method.

TAB:Tape Automated Bonding

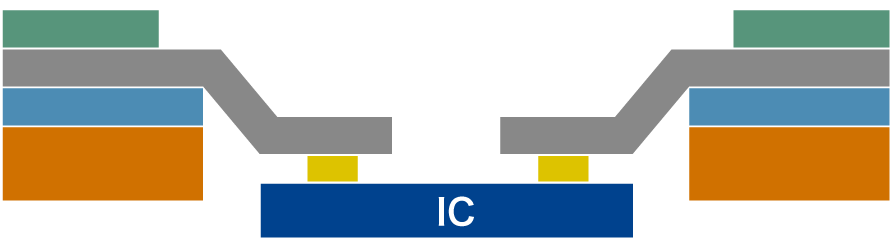

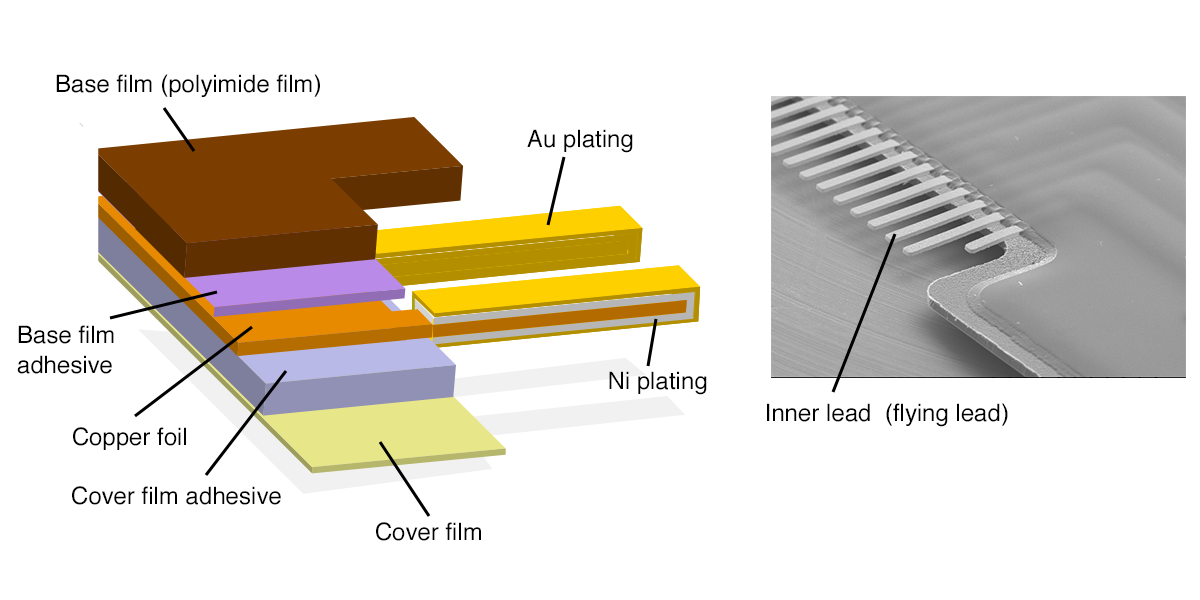

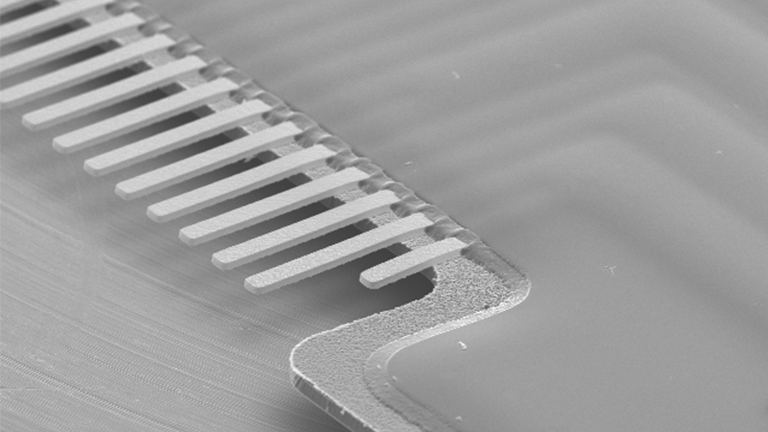

A TAB flexible board has a single-sided wiring structure. It bears connection holes, called contact holes, in the board that enable electrical connection from the back side.

We use the reel to reel method to manufacture various flexible printed wiring boards, offering services from prototype to mass production and mounting.

We use our proprietary transfer technology (the reel to reel method) to mount flexible printed wiring boards, or use sheets to mount printed wiring boards (rigid / flexible), depending on the needs.

| subtractive (etching) Method | ||

|---|---|---|

| 【mass production】 | 【Under development】 | |

| structure | TAB | COF |

| Single sided | ||

| L/S(MIN) | 35/40, 35/45µm | 25/25µm |

| Base material thickness | Ad: 12µm PI: 50µm |

25µm・38µm |

| Copper thickness (Circuit thickness) | 25µm, 35µm | 8µm・12µm |

| Circuit protection | Cover lay | Cover lay・Resist |

| Terminal surface treatment | Electrolytic Ni Au | Electrolytic Ni Au |

| Outer Dimension size【 mm 】 | Min10×10 Max60×120 |

Min10×10 Max60×120 |

| Outer Dimension accuracy | ±0.2mm | ±0.2mm |

| PT distance from the edge | 0.8mm or more | 0.8mm or more |

| Production Form | R to R | |

We can support the production for mass volume by the Reel to Reel method and for many kinds of small quantity by the sheet size delivered production

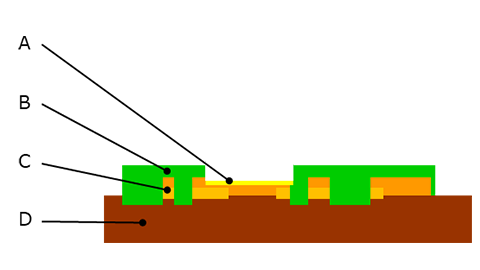

Layer structure (Reference)

| Single side printed wiring boards | |

|---|---|

| Layer structure | Layer Specifications |

|

A:Terminal treatment ※ B:Wiring protection layer ※ C:Wiring layer Copper foil and Copper plating D:Interlaminar Insulating layer Polyimide |